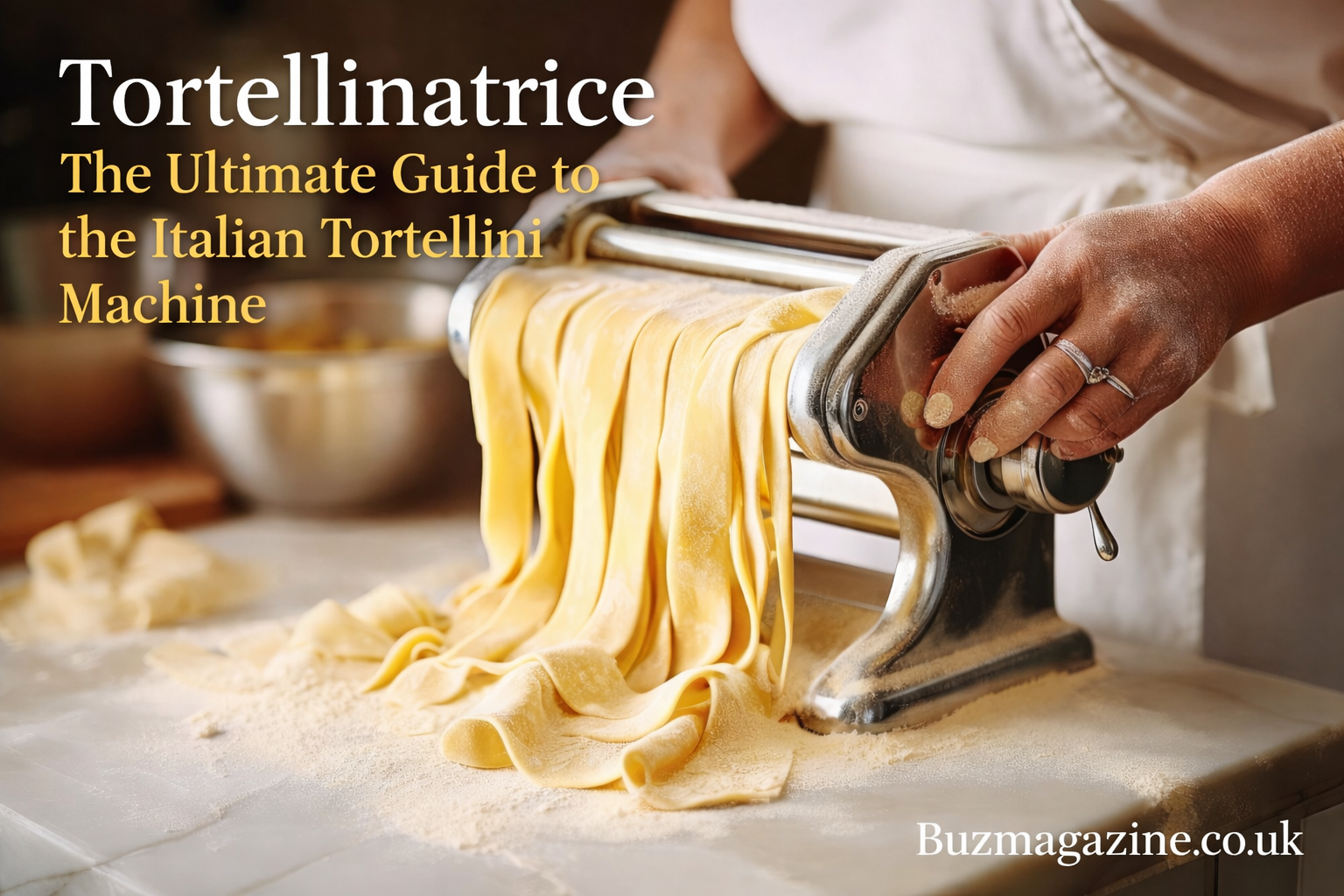

Tortellini — those iconic little pasta rings filled with rich meat, cheese, or vegetable fillings — are beloved throughout Italy and around the world. Their handcrafted preparation is steeped in tradition and celebrated in kitchens from Emilia-Romagna to New York. But as demand for fresh, artisanal pasta has grown, so has the need for efficiency without sacrificing quality.

Enter the tortellinatrice — a specialized pasta-making machine designed to automate and perfect the process of making tortellini and similar stuffed pasta. From home kitchens to industrial facilities, the tortellinatrice is revolutionizing how this cherished Italian delicacy is produced.

In this comprehensive guide, we’ll explore everything you need to know about the tortellinatrice — how it works, why it matters, and how you can choose the right one for your needs.

What Is a Tortellinatrice? (Quick Answer for Featured Snippets)

A tortellinatrice is a specialized machine created to automate the production of tortellini — from rolling out dough sheets to portioning filling, folding the pasta into the signature ring shape, and cutting the finished pieces. Unlike traditional pasta rollers, a tortellinatrice handles multiple steps in one streamlined process, producing consistent, high-quality results at speeds far beyond what’s possible by hand.

In simple terms:

- It automates the labor-intensive parts of tortellini making

- It ensures consistency in size, shape, and filling

- It speeds up production from dozens to thousands per hour

- It bridges tradition with technology for chefs, manufacturers, and home cooks alike

Meaning, Etymology & Italian Origins

The word tortellinatrice combines “tortellini” — the iconic stuffed pasta — with the Italian suffix “-atrice,” which denotes a device or machine. It literally means a tortellini-making machine.

Italian Culinary Roots

Tortellini originated in the Emilia-Romagna region of northern Italy, particularly in the historic cities of Bologna and Modena, where pasta is an integral part of culinary heritage. This region also gave birth to many other renowned Italian specialties — from Parmigiano-Reggiano to balsamic vinegar — showing the cultural weight of Italian pasta.

Traditionally, making tortellini was a family craft passed down through generations. Artisans known as sfogline would spend hours hand-rolling dough, cutting squares, placing fillings, and folding each piece precisely. Even today, some establishments in Bologna produce tens of thousands of tortellini by hand each day, a testament to both skill and dedication.

As demand for fresh pasta increased globally — fueled by Italian culinary influence, restaurant trends, and the international market for authentic pasta — the need for mechanized production grew as well. The tortellinatrice represents this evolution from handcraft to industrial and artisanal automation.

How a Tortellinatrice Works (Step-by-Step Breakdown)

At its core, the tortellinatrice automates multiple steps in the tortellini-making process that traditionally required manual effort.

1. Dough Preparation & Feeding

First, fresh pasta dough — typically made from high-quality flour such as “00” or semolina and fresh eggs — is prepared and rested. This dough is then fed into the machine either as a slab or pre-rolled sheet.

2. Roller & Thickness Adjustment System

Modern tortellinatrici include precision rollers to flatten the dough into ultra-thin, even sheets — usually about 0.6 to 0.8 mm thick — ensuring uniform texture and cooking consistency.

3. Filling Deposition Mechanism

Advanced machines use calibrated filling mechanisms — such as rotary or piston systems — to deposit measured amounts of filling at consistent intervals. These can be adjusted to accommodate different recipes, including meat, cheese, or vegetable blends.

4. Folding and Shaping Station

This is where the machine replicates the delicate motion of hand-folding. Rollers, molds, and pneumatic parts fold the dough over the filling and seal the edges into the familiar ring shape of tortellini.

5. Cutting and Output

Once formed and sealed, the machine cuts each piece cleanly and places finished tortellini onto trays, conveyors, or collection bins. High-end industrial models may even include sensors that reject misshapen pieces.

In summary, a tortellinatrice streamlines roll → fill → shape → cut into a single automated sequence, making production faster, more consistent, and far less labor-intensive than traditional methods.

Types of Tortellinatrice Machines

There’s no one “perfect” machine — tortellinatrici come in various forms to serve different needs and scales.

Manual Tortellinatrice

Designed for home or small artisan use, manual models use a hand-crank or basic mechanical system. They give great control and are usually compact and affordable, though output is limited.

Electric Tortellinatrice

Electric models automate the rolling, filling, shaping, and cutting processes. These are ideal for busy kitchens, small businesses, or pasta shops that need higher output with minimal manual effort.

Semi-Automatic Machines

These hybrid devices offer automation for some steps (like filling), while others remain manual — striking a balance between control and efficiency. Perfect for artisan producers and boutique pasta makers.

Industrial & Commercial Tortellini Machines

Large and high-capacity models can produce hundreds to thousands of pieces per hour — for example, some modern industrial machines handle up to 12,000 pieces/hr — ideal for factories, mass production, and large-scale distribution.

Key Features to Look For Before Buying

Choosing the right machine involves several technical and practical considerations:

Construction Material

Opt for food-grade stainless steel whenever possible — it’s durable, corrosion-resistant, and easy to clean. Cheaper plastics may reduce cost but can compromise longevity and hygiene.

Capacity & Production Speed

Assess how many pieces per hour you need. Home use may only demand dozens per batch, while commercial operations may require thousands per hour.

Adjustability and Controls

Look for tools with adjustable dough thickness, filling volume settings, and interchangeable molds. This gives flexibility for different recipes and pasta shapes.

Ease of Cleaning & Maintenance

Removable parts, accessible controls, and straightforward cleaning procedures help maintain hygiene and prolong machine life. Regular cleaning also ensures food safety compliance.

Food Safety & Compliance

High-end machines often meet HACCP and other food safety standards, which are essential for commercial kitchens and food manufacturers.

Benefits of Using a Tortellinatrice

Investing in a tortellinatrice brings tangible advantages:

Speed & Productivity

While a skilled pasta maker might shape 50–100 tortellini per hour by hand, a modern tortellini machine can produce into the thousands in the same time.

Consistency & Uniformity

Automated filling and shaping result in uniform pasta pieces that cook evenly and look professional — perfect for restaurants, retail packaging, or catering.

Reduced Labor & Waste

Less manual labor reduces kitchen fatigue and allows your team to focus on creative aspects of cooking. Precise filling reduces ingredient waste.

Scalability for Business

For startups and food businesses, a tortellinatrice enables scaling production without exponential staffing costs. Brands can grow from small batches to commercial distribution while maintaining quality.

Food Safety & Hygiene

Mechanized shaping reduces direct handling, lowering contamination risk and making compliance easier in regulated kitchens.

Tortellinatrice vs Other Pasta Machines

| Feature | Tortellinatrice | Pasta Roller | Standard Electric Pasta Maker |

| Stuffed Pasta Production | ✅ Yes | ❌ No | ❌ No |

| Dough Rolling | ✅ Yes | ✅ Yes | ✅ Yes |

| Filling Distributor | ✅ Yes | ❌ No | ❌ No |

| Shaping & Folding | ✅ Yes | ❌ No | ❌ No |

| Commercial Output | High | Low | Medium |

A tortellinatrice is unique because it does multiple steps in one integrated workflow — unlike simple pasta rollers that only handle sheets and basic cut shapes. This makes it indispensable if your goal is filled pasta like tortellini, ravioli, or cappelletti.

What Types of Pasta Can a Tortellinatrice Make?

Despite its name, a tortellinatrice isn’t strictly limited to tortellini:

- Tortellini

- Ravioli

- Agnolotti

- Cappelletti

- Mezzelune

- Even experimental stuffed pastas like dessert or fusion pasta

The key is having the right molds and settings, which many machines support through interchangeable attachments.

How to Use a Tortellinatrice at Home (Beginner Guide)

Ingredients Needed

- High-quality flour (type “00” preferred)

- Fresh eggs

- Fillings (ricotta, meat, pumpkin, spinach, etc.)

- Salt, spices, herbs

Begin by mixing flour and eggs until you form a smooth, pliable dough, and let it rest.

Preparing the Dough

Roll the dough with your machine’s sheeter until you achieve a thin, even sheet.

Preparing the Filling

Balance flavors and moisture — filling too wet can cause poor sealing; too dry can result in crumbly edges.

Machine Setup & Calibration

Adjust thickness settings and feed the dough into the machine. Set filling volume based on your recipe.

First Batch Tips

Start with simple fillings and monitor the output for shape, seal, and uniformity.

Cooking & Storage

Fresh tortellini cook quickly — usually 2–4 minutes in boiling water. Alternatively, freeze for later use.

Homemade vs Commercial Use

Homemade Cooks

Perfect for enthusiasts, dream kitchens, and pasta parties. Manual and tabletop models offer fun and control.

Restaurants

Professional kitchens benefit from consistency and speed during service hours.

Pasta Startups

Small food brands can expand offerings without manual bottlenecks, enabling packaging or local delivery.

Food Manufacturing

Large facilities use industrial models to feed retail supply and global pasta markets.

Buying Guide — How to Choose the Right Tortellinatrice

When investing in a machine:

- Define your production volume

- Set a budget range

- Confirm power source and size

- Evaluate brand reputation

- Ensure after-sales support

Popular industry brands often provide warranties and spare parts — crucial for long-term reliability.

Common Mistakes to Avoid

- Using dough that’s too sticky or too dry

- Overfilling the pasta

- Not calibrating thickness correctly

- Skipping regular cleaning

- Ignoring manufacturer’s maintenance guidelines

Cleaning & Maintenance Guide

Routine cleaning prevents hygiene issues and ensures machine longevity:

- Remove and wash detachable parts after each use

- Clean rollers and filling heads thoroughly

- Use food-safe lubricant on moving components

- Store in a dry, clean environment

Cost, ROI & Business Potential

Is a tortellinatrice worth it?

For home cooks, a machine saves hours of manual labor. For businesses, it can reduce staffing costs and increase throughput — potentially doubling or tripling output relative to manual production, depending on model and scale. Investment returns quickly when selling fresh pasta, meal kits, or packaged tortellini.

Future of Tortellinatrice Technology

Advancements may include:

- App-controlled settings

- AI-assisted filling calibration

- Smart monitoring for quality control

- Integration with food production software

Such innovations could further smooth the gap between artisanal quality and industrial efficiency.

Real User Reviews & Testimonials

User experiences often praise the tortellinatrice for:

- Consistency of pasta shape

- Ease of use compared to hand folding

- Time savings during production

Professional kitchens report higher throughput and more uniform dishes, while home users enjoy newfound convenience without losing authentic flavor.

Frequently Asked Questions (FAQ)

1. What is a tortellinatrice used for?

It’s used to automate the production of stuffed pasta like tortellini, handling dough rolling, filling, shaping, and cutting.

2. Is a tortellinatrice beginner-friendly?

Yes — many models are designed with intuitive controls suitable for novices and experts alike.

3. How many tortellini can a machine make per hour?

Industrial models can produce thousands per hour — some up to 12,000 pieces/hr — while home models are slower but still faster than hand folding.

4. Can a tortellinatrice make other stuffed pasta shapes?

Yes — with the right molds, it can make ravioli, agnolotti, cappelletti, and similar stuffed pastas.

5. What materials are best for a tortellinatrice?

Food-grade stainless steel is preferable for durability and hygiene.

Final Thoughts: Is a Tortellinatrice Right for You?

Whether you are a pasta enthusiast or a commercial producer, the tortellinatrice represents a powerful blend of tradition and innovation. It honors Italy’s rich culinary history while giving modern kitchens the tools to create consistent, delicious pasta at scale.

From backyard kitchens to artisan pasta shops and large manufacturing plants, the tortellinatrice is more than a machine — it’s a portal to elevating tortellini from hand-made tradition to efficient contemporary craftsmanship.

ALSO READ: Florncelol – A Deep Dive into Its Meaning, Cultural Impact, and Digital Future